1970 C-10

A 1970 Chevy C-10 that was in rough shape is the project vehicle here. It was a long bed, which was shortened to a short bed sometime in the past. The transmission had a cracked fitting, leaking ATF, the rear brake drums had to be cut off. So there was a lot to do to get this C-10 back to being a safe streetable head turning cruiser.

Read through and find bonus video about this project at the bottom!

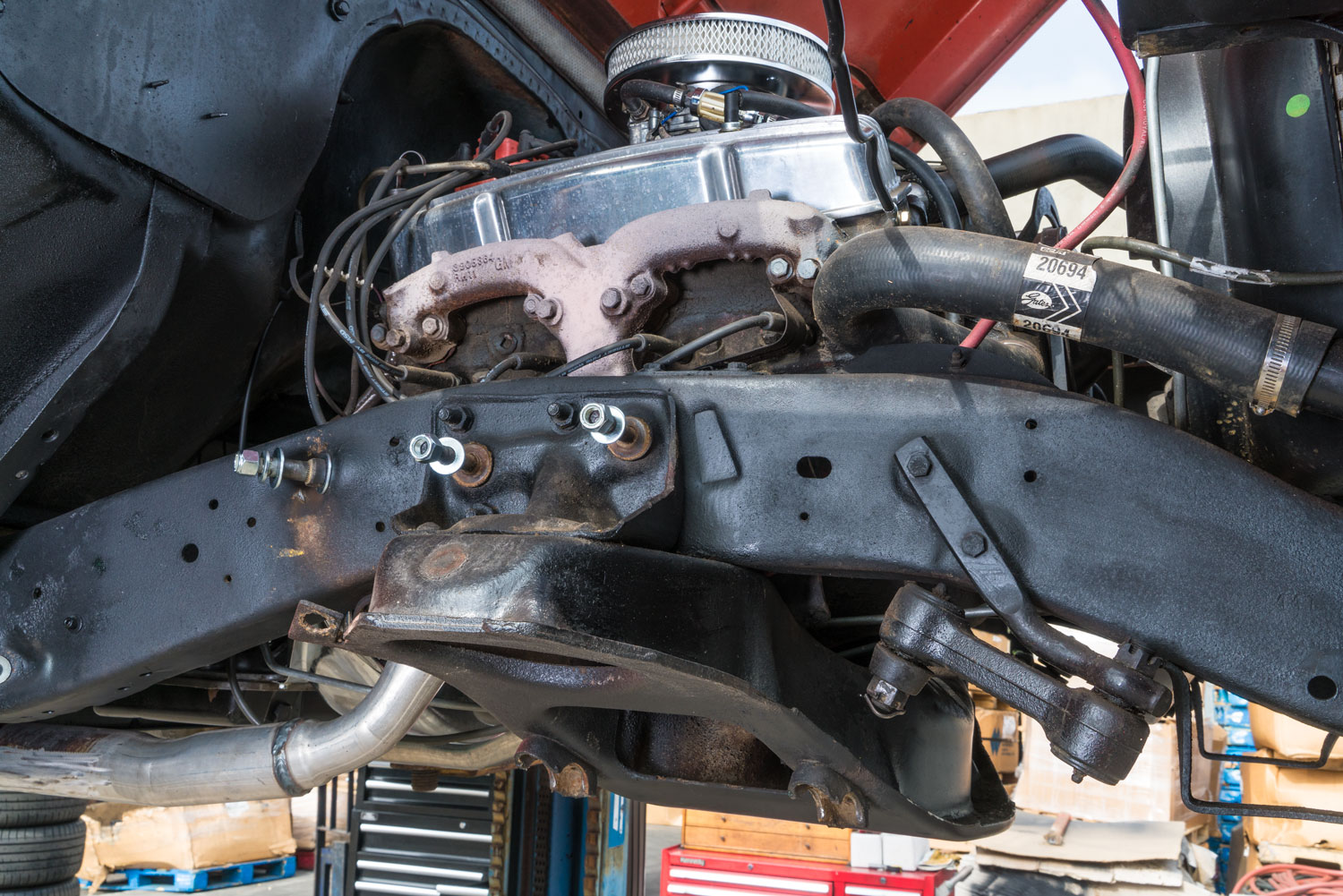

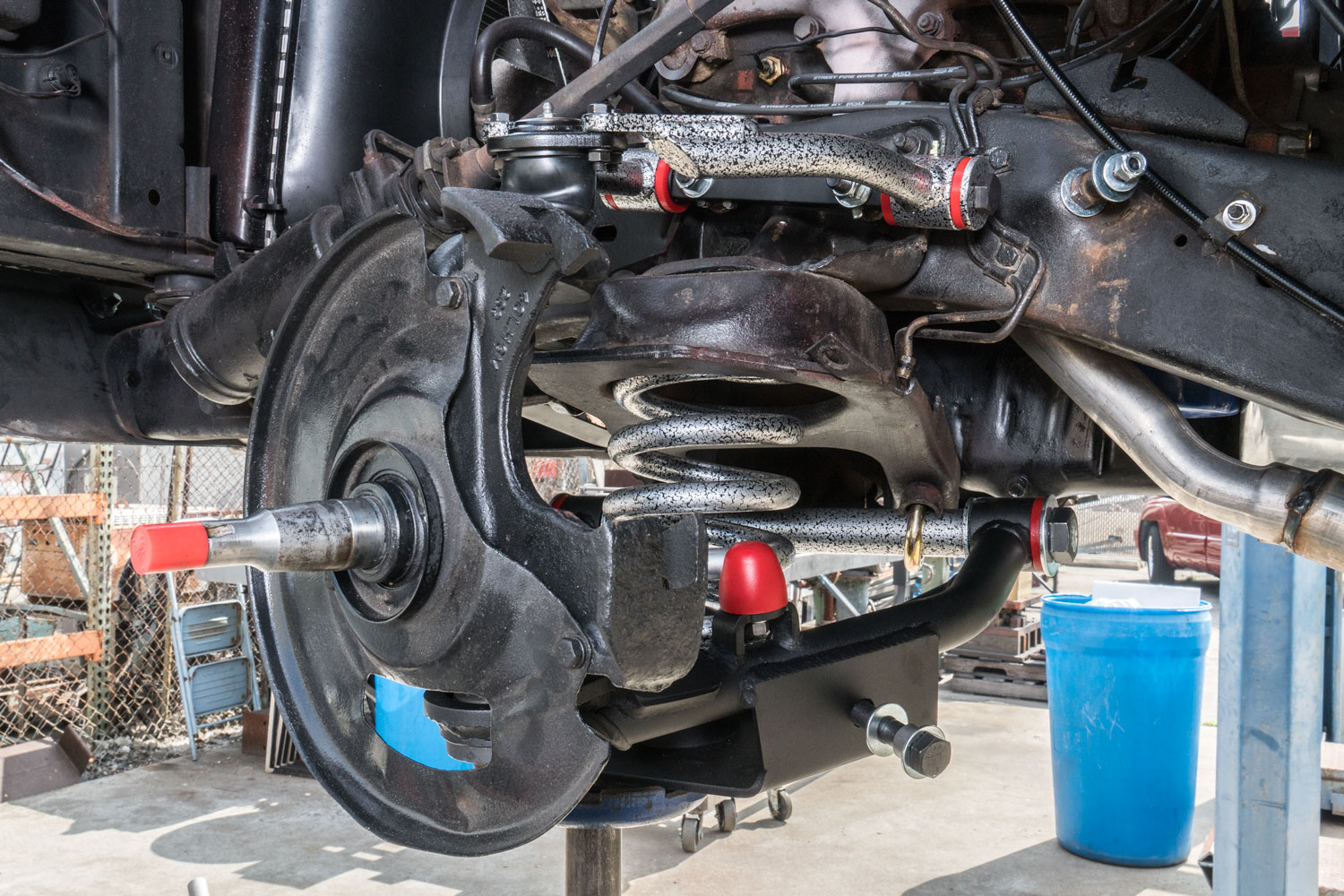

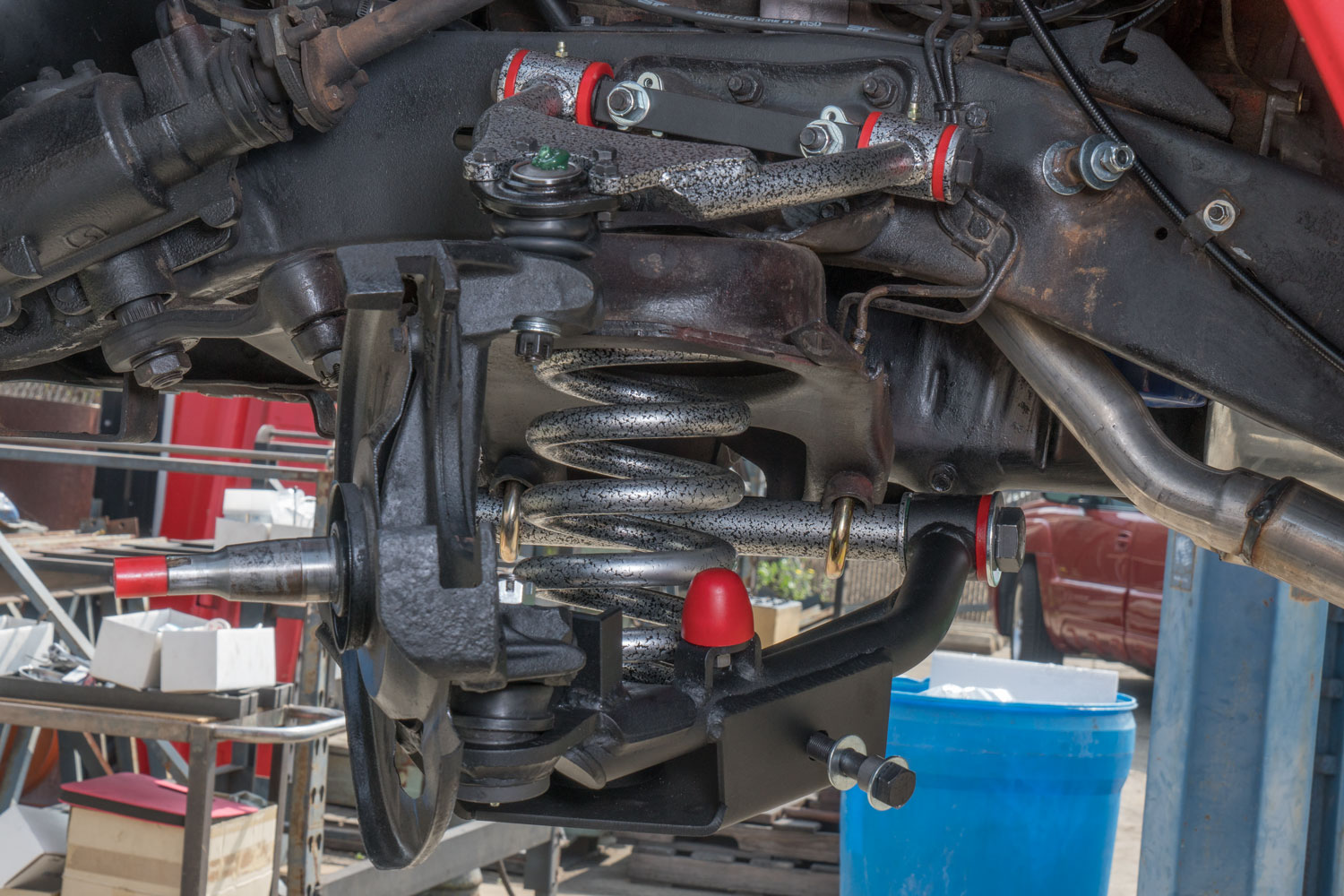

The front end had also been converted to disc brakes with a drop spindle/spring combination, keeping the original upper and lower control arms, ball joints, bushings, etc.

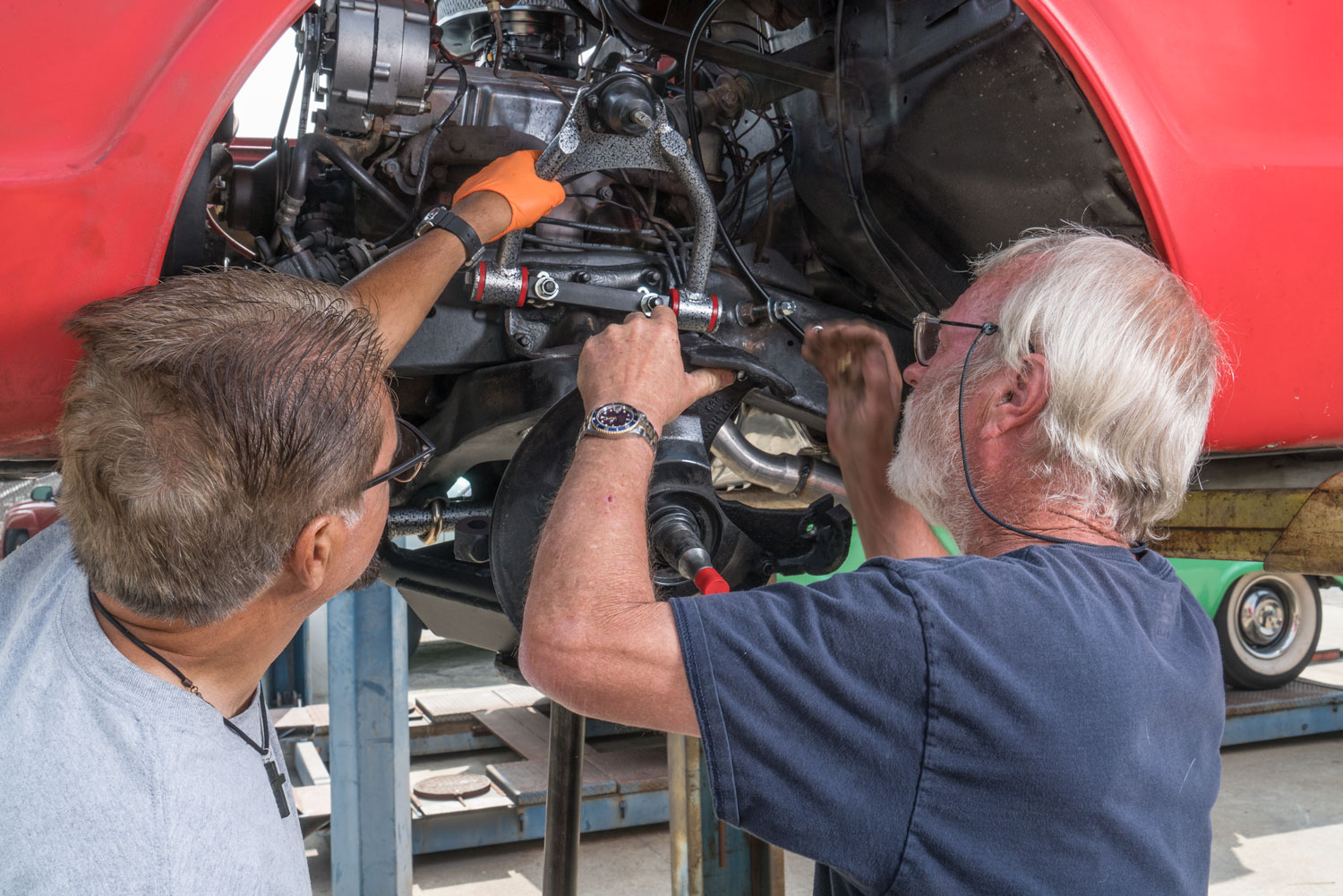

After removing the old tired suspension we cleaned up the frame and suspension mounting points, removed and repainted the fender liners making much easier to install our Calmax Control Arms, plus it gives you great access to the engine!

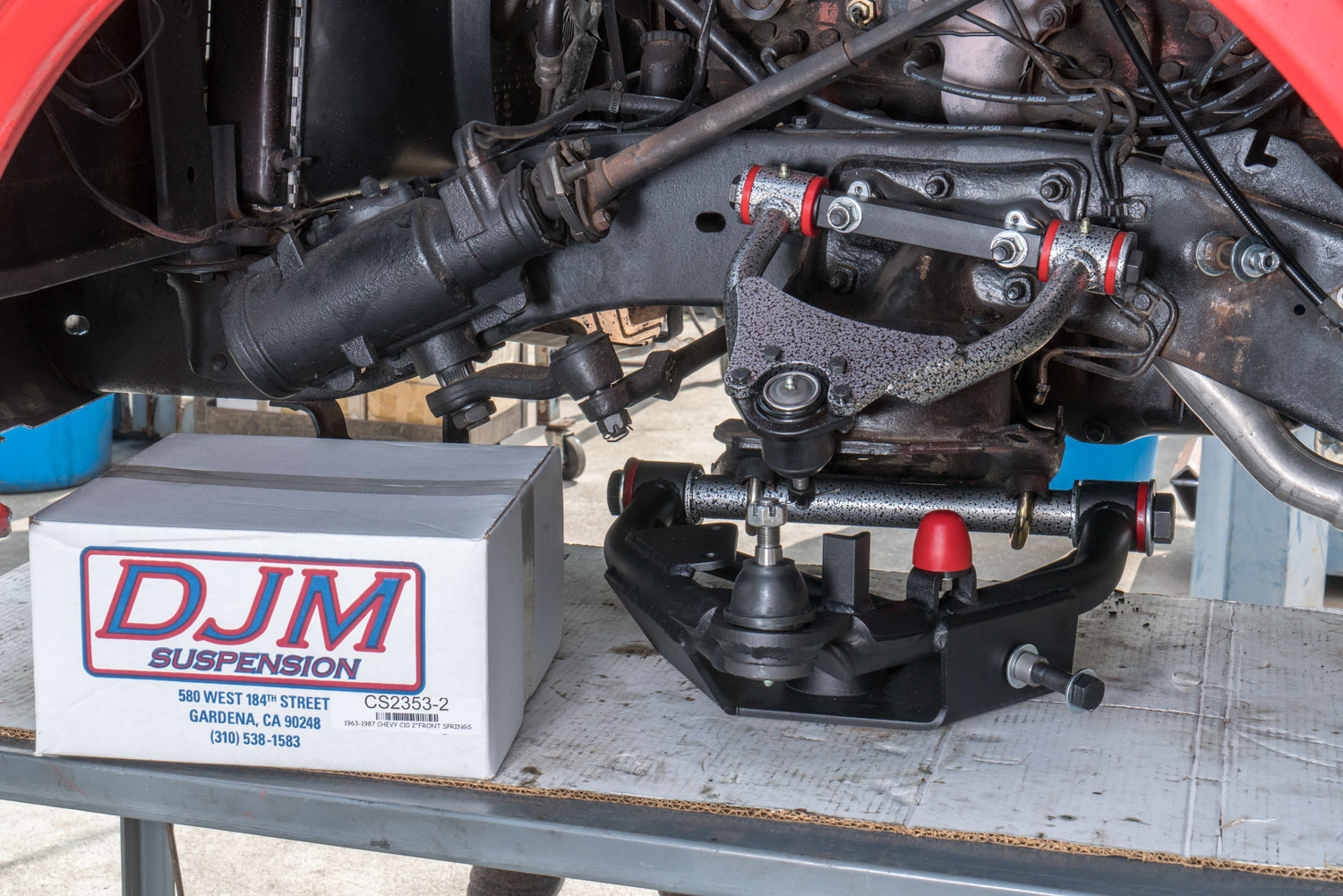

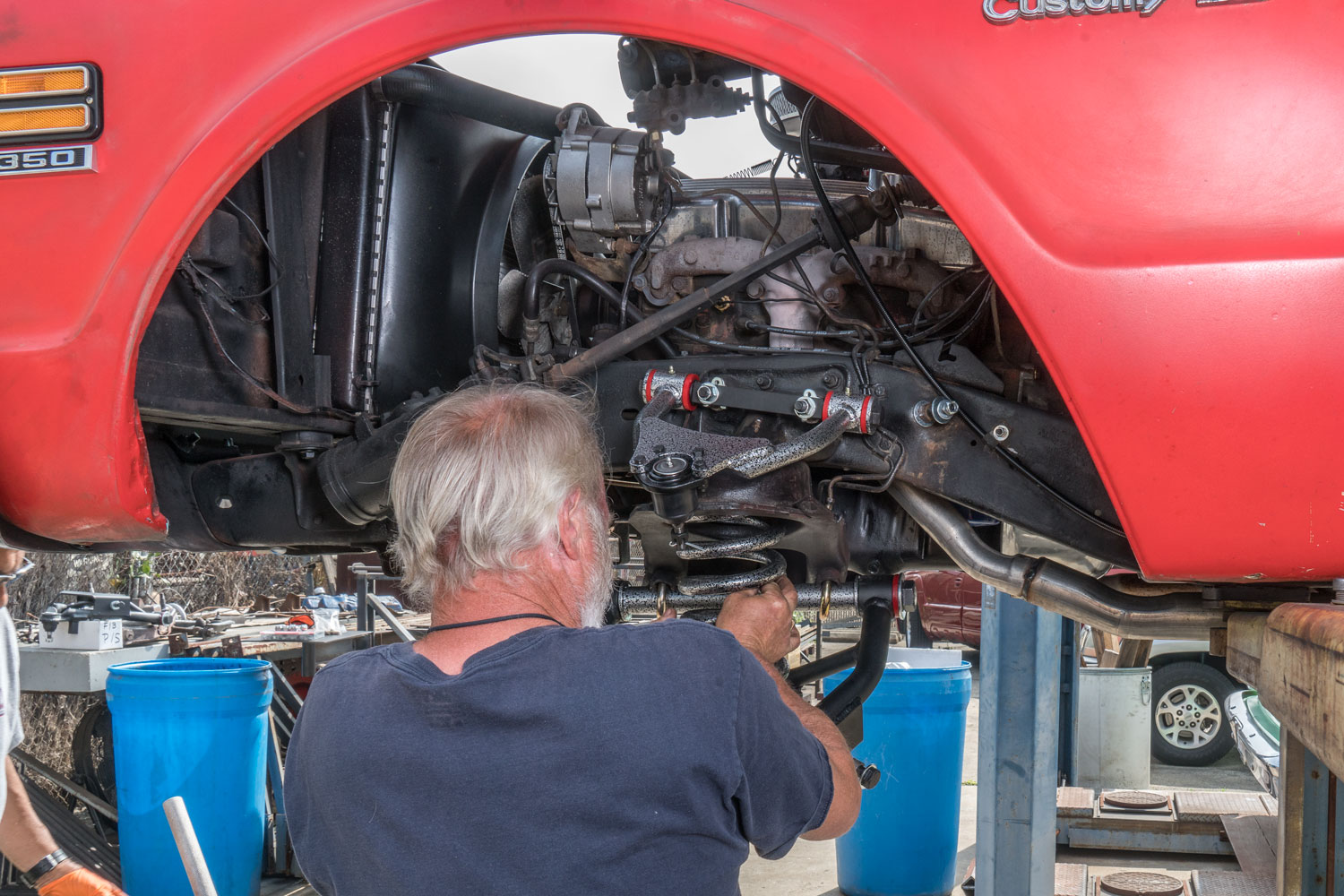

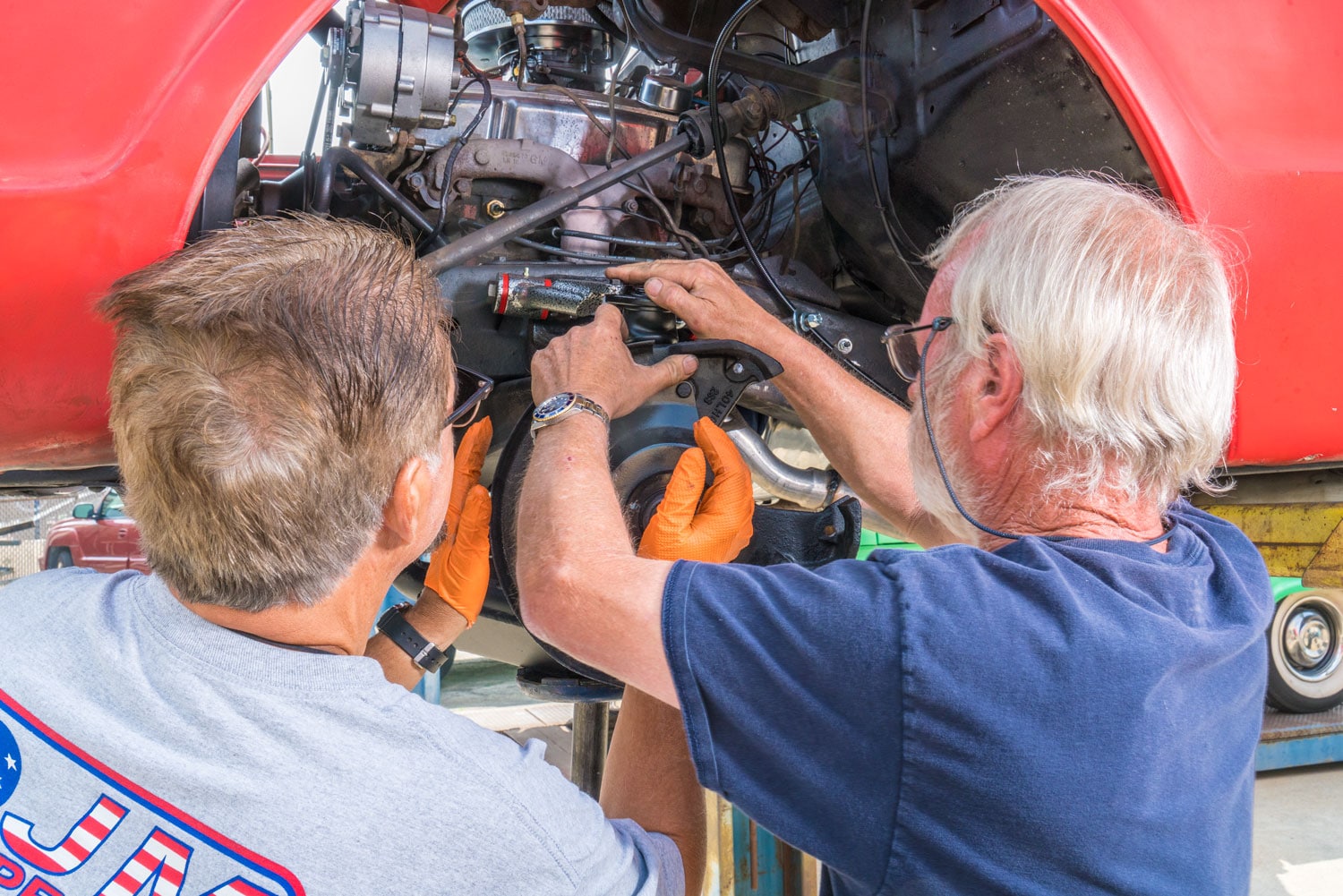

Calmax control arms for C-10’s have brand new mounting shafts and new urethane bushings installed so you just pull the upper control arms out of the box, bolt in your new ball joint, grease zerks then mount right to the frame.

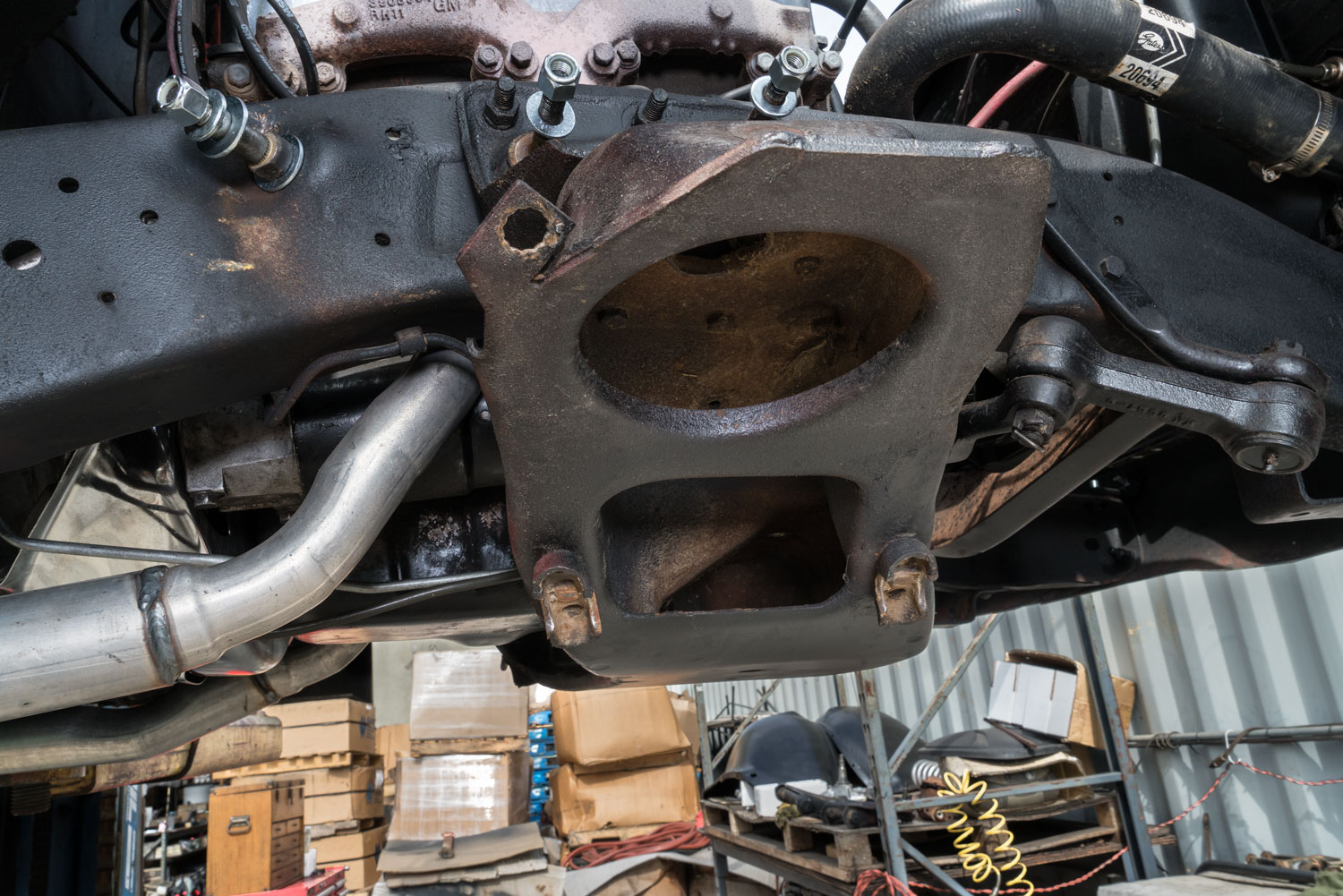

Just like the upper Calmax arms the lowers have the mounting shaft installed and the new ball joints are pressed in so you don’t have to! Be careful to install you grease zerks and lubricate everything before you install the arms. Depending on the condition of your truck you may want to replace the u-bolts that secure the lower control arms, we decided to do this. One of many things replaced or upgraded on this C-10. You have all new moving parts, lubricated ready to go!

The next step is installing coil springs. We’re using a 2” drop coil with the Calmax lower control arms to get a 5” drop on the front. Important here is to seat the coils spring properly in the control arms and the upper spring mount. Using 1975 original equipment spindles to keep the disc brakes on this 1970 we install our 2” drop coil springs, brake rotors and calipers.

As noted before this 1970 C-10 was born a long bed and was shortened before we got a-hold of it. Like the front we removed everything and cleaned up the undercarriage in the rear.

With everything completely removed including the rear end, we set about fixing the rear brakes. The original drums had to be cut off and we found the rear brakes probably didn’t help stop this C-10 very well. So a complete overhaul was necessary! Easier to do when the rear end is out of the truck!

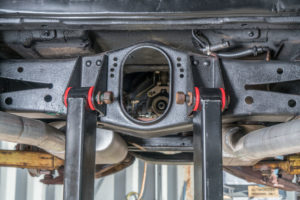

A good clean start with new parts for the rear drop. This truck was used to design replacement trailing arms and frame reinforcement (c-notch) brackets for the C-10 platforms with rear coil springs. Since everything was removed we went ahead and built a greasable tubular panhard rod and will install our DJM rear drop coils on this 1970 C-10.

Our new DJM trailing arms compared with the factory arms.

The new trailing arms have the famous DJM “Twin Tube Sleeve” design built into the pivot bushings and before installing we greased these joints up good! Sliding the new trailing arms into the factory location is pretty easy but we’re not going to tighten up yet. Time for the cleaned up rear axle with those new brakes to assume it’s proper place. Using a strong shop cart and jack stands we could mate the rear axle with the trailing arms. Note we’re using our spacer block kit to get even more drop on the rear end! Next, the DJM lowered Coil springs were installed and lower shock mounts.

The New DJM Trailing Arms will be available soon stay tuned

The new tubular panhard rod is installed

The frame was cut with a half-pipe welded in to attempt to reinforce the frame when it was lowered and shortened in the past. We used a plasma cutter to cut the frame to match the c-notch bracket, then created the bolt holes so we could bolt the new frame supports in place, giving the frame much more strength than it had with the prior modification. Bolting the frame support in place with 5/8” bolts looks good and really beefs up the frame, allowing for plenty of axle clearance.

Of course, we used Calmax Supershocks to finish up the rear suspension. Now its time to tighten everything up and check over the suspension.

Installing the drive shaft

Here's a great way to align your front without using those pesky shims!