Cody’s F100

In his own words Cody gives us a blow by blow description of the suspension install with lots of pictures. You'll see just how cool it is to lower these older king pin "Effies", and why they are becoming so popular!

Story and Photos by Cody Ramer

Installation

I started with the back of the truck, DJM hangers and shackles. I lifted the truck by the frame and put a jack under the rear end. Unbolt the shackles, for the top bolt on the shackle you need to jack the rear end up to where the top bolt can clear the top of the frame. You will need to install the top bolt with the nut on the outside (should be the same way it came out.) If you don’t you will run into clearance problem later.

There are two arms that come off the bottom of the bed and go in front and behind the rear fender, the rear one take off and discard. You will need to notch the bottom of the bed for clearance, where you took off that arm. (I have a picture.) The hangers were straight froward. I used a air hammer with a chisel knocked the heads off the rivets on the outside of the frame, then used a punch bit to knock them out, the only problem I ran into was with the bottom two rivets on each side they have a plate on the inside of the frame, you will need to chisel off that head also then punch them out. ( A torch might of worked better.) Then just bolt the hangers right up to the original holes. I did put the leaf spring on the hanger before bolting the hanger to the frame. Shocks were easy unbolt the old ones and in with the new.

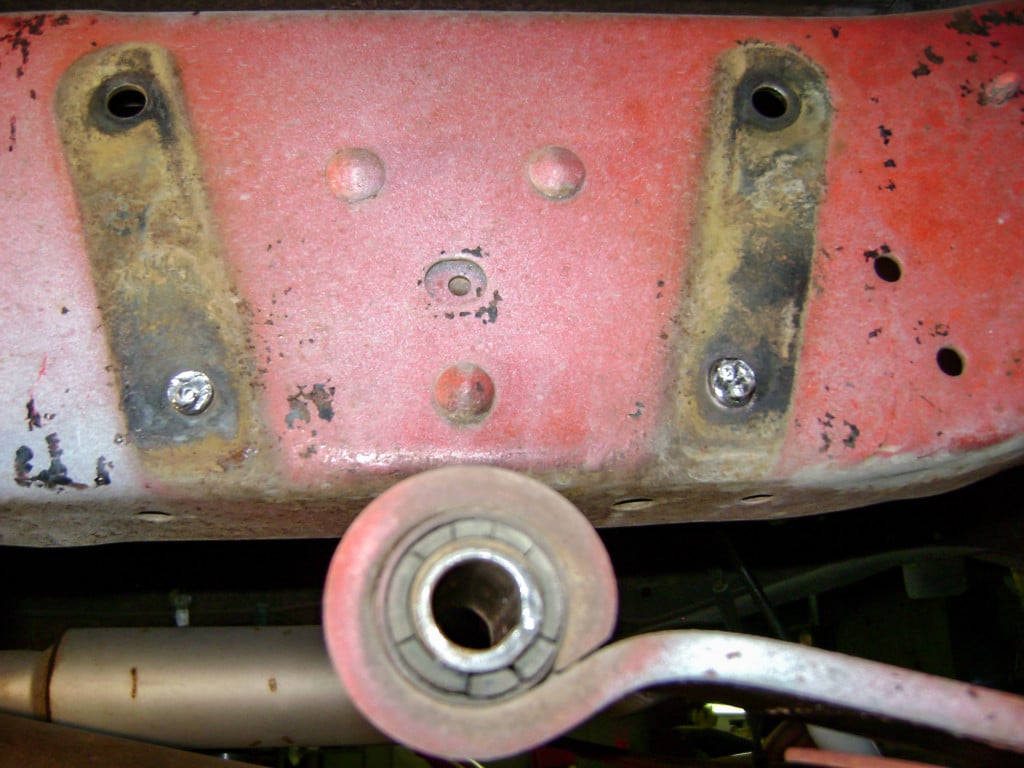

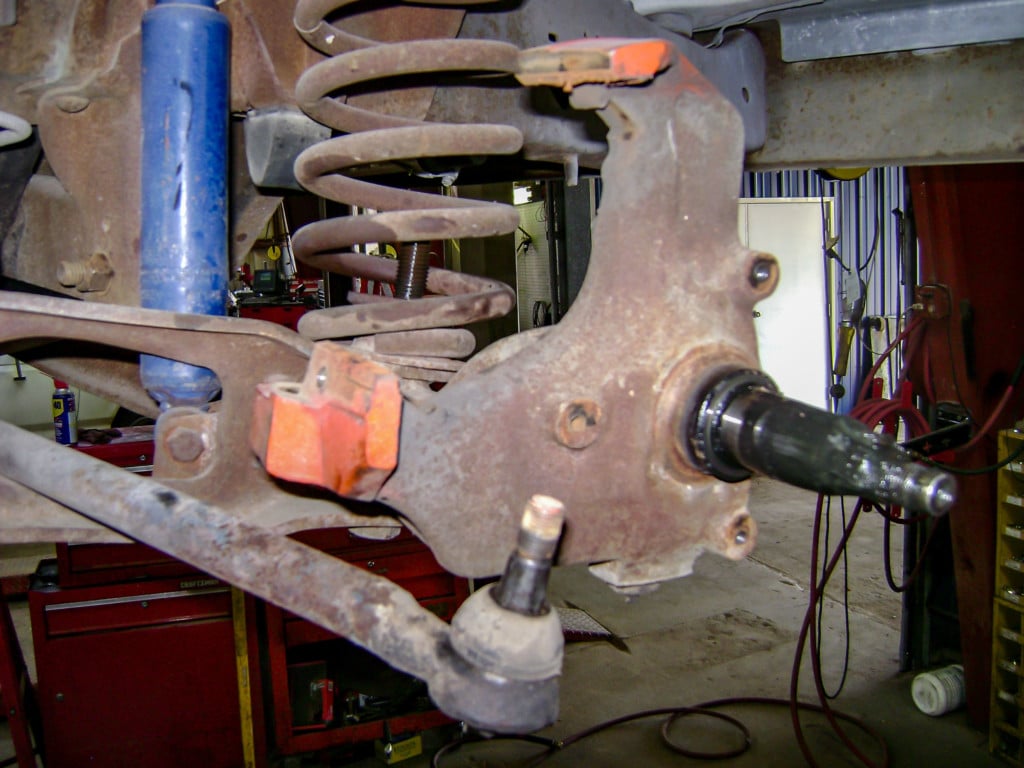

Now to the front DJM dream beams. Start by taking the caliper off, then the rotor, there is a shield with three bolts, real easy to get to take off. (I went ahead and packed the bearings and turned the rotors while I had them off.) Then take the nut off of the tie rod and pop it out. (Hit the spindle where the tie rod goes through it to knock out the tie rods.) Now the coil spring, you will need a open end wrench to take the nut off inside the spring. Then on the top of the coil spring there is a bracket with two bolts that hold the spring on the top take them off. Now put a jack under the I beam and put a little pressure on it. Now the bottom bolt of your shock, take it out, then slowly let the jack down the coil spring will come out. There is another nut on the bolt that went up into the coil spring take it off. Then one last bolt where the I beam bolts up to the frame. Now you can take the beam with the spindle to a work bench, helps to have vice take the nut off the pin that hold the king pin in place knock it out, take off the grease caps knock out the king pins, and get your dream beam and put it all back together. Put the tie rod extender on the spindle, (you do not have to tighten it up yet.) Then when you are going back on with the coil spring get your tie rod started in the tie rod extender. Now if you forget to start the tie rods you can take the pitman arm off and get them that way.

The Story Behind Cody's F-100

Cody sent us more "Beauty Shots" of his F-100 and the story behind this particular "Effie"

I was 16 years old, a sophomore in high school, when I got my first truck. It was a gift from my Uncle Thom. Before he gave it to me he had the seat reupholstered, a new head liner, and new carpet put in it for me. When he gave me the truck I knew right away that I wanted it to be a custom truck. I had been hooked on truck magazines since I was in the 5th grade, and now it was time for me to put all my ideas to work. Since I was still in high school, living at home with my parents, I worked part time at the local grocery store sacking groceries to earn money so I could fix my truck up. In my spare time I would work on my truck in my parents carport.

The first thing I had to do when I got the truck was put a sound system in it. I have always been a big guy, I am 6 foot 6in., So I knew there wouldn't be much room behind the seat for me to install speakers. I decided to cut out the back of the cab and weld in boxes that would go through the bed. I lined the inside of the boxes with wood and spray foam to help maximize the sound. I also cut out under the seat belt straps to add some 6x9's. This was my first bit of customizing.

My next project was to work on shaving the bed caps, mirrors, doors, and emblems. I did not know how to do any of this at the time so I warped a lot of it, but you have to learn some how. Then the next thing to be shaved was the tail lights, I bought a smooth roll pan, and 4 oval LED tail lights. I put the lights in the roll pan, and welded in the old brake tights. It just didn't seam like it was enough so I decided to add a 3rd brake light, a 12in. LED. I made a box for it and frenched it in on top of the cab. The back of the truck was looking pretty good, but not quite good enough so I decided to make a custom tail gate. I bought a new tail gate with the intention of making it so that it could open. I made it with a frenched in license plate sideways, like I had always wanted. After this I looked at it and thought to myself why not shave it all in? So that’s what I did. There was a lot of welding on the back of that truck, but I must say its my favorite part of the truck.

I was also working on stripping the truck to bare metal while doing the mods. I would get a bed side striped over the weekend and next week I would have to drive to school and work, it seamed like it would only rain if I had a part down to bare metal. So next weekend I would be out there striping the rust off I would do this over and over until I finally got a chance to prime it.

I would like to thank God for blessing me in so many ways, and with so many special people in my life. My parents Kim and Jim. Mom didn't really like me working on my truck because her carport was always a wreck. Dad always supported me and thought it was great. My parents didn't just give me everything, they taught me to work hard and do my best no matter what I did. My wife Brittany, although she and I had just began dating when my truck was almost finished, she has been very supportive of me. My good friend Jim Golden who now works in a body shop as a painter, and is also co founder of our club Kustoms and Kruzers. My sis Tiffany, she lives pretty far away, but always took an interest in my truck and the progress I was making. Some of my other good friends I would like to mention are Anthony, Coy and Nevada. They were always there to lend a hand, and help any way they could. Mark Dunham at DJM suspension for helping me bring my truck closer to earth, it looks so much better. Last but not least my Uncle Thom. Without him I never would have got the truck and may never of built a custom truck. So a big thanks to you Thom.

What DJM Kit did Cody Use?

The famous DJM Dream Beam set up for king pin Fords. Find out more? Click on the button.