Super Shocks

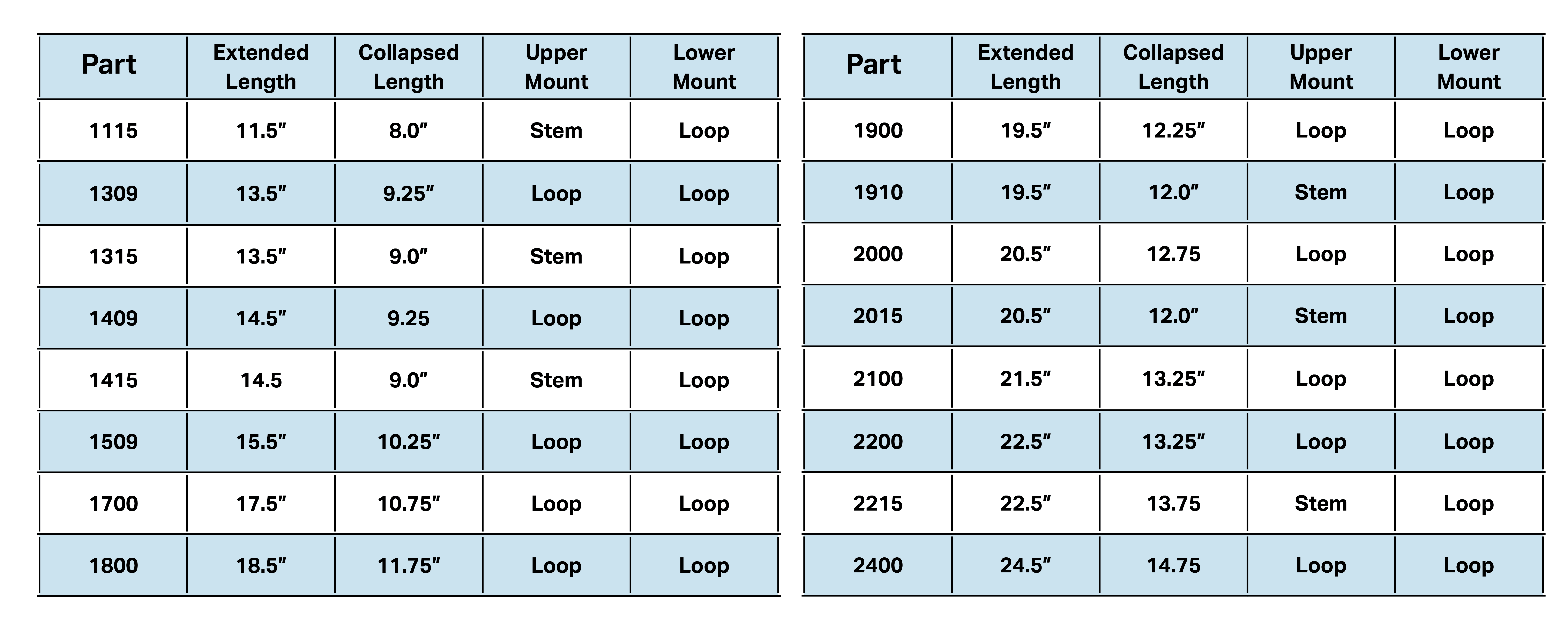

Use this chart to find the correct shock for your truck.

SHOCKS – WHY?

Shock absorbers are a very important part of a “tuned” suspension.

To best understand how shocks work, think shock controller rather than shock absorber. That is, after all, what shocks really do. It is the job of your coil/leaf springs (or torsion bars) to actually absorb shock. When you hit a bump or dip in the road, it is the springs that react by absorbing the impact, by compressing and expanding (moving up and down). It is the shock which controls the rate of reaction of the spring. They “control” the springs as they expand and contract. Or said another way – the shocks allow the suspension to dissipate the absorbed energy of bumps and dips in a controlled and comfortable fashion. You have all seen cars or trucks bouncing up and down the road on occasion. This looks silly, is very uncomfortable for the passenger, and can make the vehicle dangerous for the occupants. Remember your high school physics class. Newton’s first law of motion – “Unless acted upon by an outside force, a body at rest tends to stay at rest, and a body in motion tends to stay in motion”. Now if you conducted a science experiment and removed your shocks and went for a ride you would notice how right Newton was. Once your truck starts bouncing it tends to continue bouncing, and bouncing, and, if that’s not bad enough, you could lose control; lose your girlfriend and even lose your lunch. In addition to the unwanted bounce, your shocks are the first line of defense against unsafe brake dive. (Remember from the alignment page how your alignment changes as your suspension cycles). This can cause the truck to handle poorly when you need it to behave at its best. Obviously you don’t want to make the wrong choice with your shocks.

SHOCKS – HOW

What makes a shock “tick” and how do you choose the right shock? Everybody has seen a shock, right? But what’s inside that thing? Basically, it’s a tube of oil with a piston on a shaft that moves up and down through the oil. The piston has holes that allow the oil to pass through. The size and number of holes dictate the resistance to movement as the piston is pushed down and pulled back. This is called “dampening”. You have probably tried to push in a shock and then pull it back, you felt the “dampening effect. It’s pretty hard to push and pull on a shock, good isometric exercise, but not a good way to judge a shock. This is the force however, that controls your spring. Back to our science experiment. You know how to “control” that spring that’s bouncing and bouncing and bouncing down the road–add a shock. The spring uncontrolled will tend to compress and expand and compress and expand and compress and expand (Newton) as long as you drive. Add the “shock absorbers” to this dynamic with its resistance to movement and you have a combination that result in a very comfortable ride even when lowered. Science Rules! also Good Design! Speaking of design, virtually all shock manufacturers claim to have the best design and use the highest quality materials. However not all of these “bests” are equal. There are several different types (or designs) and we will explore them now.

SHOCKS – WHICH ONE?

So how do I choose the best shock for me? Could be a tough question, but it doesn’t have to be. Let’s talk about a couple of things that can confuse the decision. WARRANTIES & QUALITY. Does a “Lifetime Warranty” mean it’s a good shock? Like the “best design” and the “best material” arguments, the lifetime warranty has become a common place marketing tool. Every shock on the market today has a lifetime warranty regardless of price or quality. If everything else is equal, your impulse might be to buy the least expensive one and save some dough. Good design and good craftsmanship cannot be replaced with a lifetime warranty. Sure, you may get a free shock to replace that leaker. But how free is it to have to either do the labor, or pay for the labor to replace the bad part? And for this luxury you will settle for a poorly performing set of shocks (bounce, bounce, remember Newton). Good design and quality materials will perform better at all times and for a much longer time and still be fully warranteed. The shocks job in your tuned suspension is too important to go lightly on the shocks.

SHOCK DESIGN

For lowered trucks and SUV’s there are two predominate designs: “Twin Tube” and “Mono Tube”. Of these, there are also two designs “Gas Charged” and “Hydraulic”. Let’s start with “Gas Charged” because you can’t throw a rock without hitting a gas charged shock. Plus we can explain both gas and hydraulic at the same time. A gas charged shock is a hydraulic shock with a gas charge! Wow, that explains everything! No, really it’s that simple, and this is why. The oil in the tube where the piston moves up and down is hydraulic fluid or oil. There is a reason why oil (hydraulic fluid) is used in ALL shocks. Back to physics class. Fluids cannot be compressed. No matter how much pressure you apply to the oil, the volume of oil in the tube will not change. A very important characteristic of the shock’ s function. The dampening effect would be comprised if the oil would “squish” as the piston was forced through it. This constant resistance provided by the oil is key to good shock design. You can change the viscosity (thickness) of the oil to change the dampening rate (also the size of the holes in the valve) A shock can be designed with very specific results in mind. A lowered truck is a good example. Where does the gas come in? Remember the shock absorber’s job is to take the shock (bumps) absorbed by the springs and dissipate that energy. This the shock dutifully does by converting that energy into heat. Now it just so happens that oil’s number one enemy when it comes to being a consistent fluid for the piston to move up and down in is heat. The oil in the shock will heat up as the piston moves and enough movement will take place to heat the oil to the point that it cavitates. Hey man, I just wanted to get a good set of shocks, and I didn’t like physics class in high school. What is cavitates? There is air in solution in the oil and when it gets hot enough little bubbles of air form in the oil and it foams. When this occurs the air bubbles are forced through the holes in the piston. The dampening effect is seriously reduced. A good shock becomes a bad shock. Ok, so where does the gas come in? This phenomenon is called “shock fade” As you’re driving your shocks may get hot enough for air bubbles to form. The dampening effect is reduced and our old physics class pal, Mr. Bounce, appears. Ok, so where does the gas come in? Back in our physics class we learned that if we apply pressure to a fluid, it can be water, can be hydraulic fluid we increase the boiling point temperature. Essentially, when the oil reaches a certain temperature in the shock at normal atmospheric pressure it boils (air bubbles/foam). If we increase the pressure in the shock tube we also increase the boiling (cavitation) point. Great, so where does the gas come in? Well because normal air even under pressure still tries to mix with the oil (causing foam) shock designers found that nitrogen (the gas) is a much better gas to pressurize the oil with. It is inert and will not mix with the oil, so you can have a lower pressure charge on the oil so cavitation does not happen and the shock performs as designed even when extremely hot. You will see “ high pressure” shocks advertised and higher pressure is necessary in mono tube shocks, but, generally speaking, enough pressure is great and “high” pressure just has a better chance to leak out!.

TWIN TUBE VS MONO TUBE

Hey, if one tube is good, then twin tubes have to be better, right? Well in the case of lowered trucks this is actually true. Let’s first look at mono tube shocks. (Roll over animation) As the name implies this type of shock has one tube with two pistons (one attached to the shaft, and one that “floats”). Both compression and rebound valves are built into the shaft piston. The “floating” piston separates the hydraulic fluid from the nitrogen gas. The gas in a mono tube design is usually much higher pressure than a twin tube, up to 360psi. This can actually help the springs support the weight of the vehicle. As you can see from the animation, the “floating” or dividing piston moves up and down with the working piston. This design can actually be mounted upside–down and still work. This is a great design and very popular with the high performance crowd, but it has two drawbacks when used on lowered truck. Because of the “floating” piston design, the shock has to be longer than a twin tube to have the same travel. With lowered trucks, travel is everything, and a premium which you just can’t give up. And because of the high nitrogen pressure mono tube shock are expensive. The cost to build a reliable, quality mono tube is high. Don’t get fooled into buying cheap “High Pressure Gas shocks”. You will be sorry. That leaves us with the TWIN TUBE design. Unless you’re racing and need the added performance of a mono tube the twin tube is the shock for you. As the name implies a twin tube shock is made from two tubes, an inner or pressure tube, and an outer or reserve tube. (Roll over animation). A low-pressure charge of nitrogen gas around 100psi is placed in the reserve tube to keep air from mixing with the oil (cavitation). The lower pressure makes the shock easier to build and since you can use most of the tube length for shock travel you have a natural design for lowered trucks. Length is a very important consideration. Depending on how you have lowered your truck, you may need to use a shock that is shorter than the factory part. But not too short. If you used a spring, you might need one shock, a control arm another. CALMAX Control arms and SuperShocks fit hand in glove on lowered trucks and it is very good to have all of your components working together.